The change to e‑mobility is in full swing. It is time for the automotive industry to change lanes: from fossil fuels and combustion engines with crankshafts, pistons and injector nozzles, to batteries and e‑drives with hairpin stators, shafts and rotors.

The challenge here lies in the fast and safe conversion of the manufacturing and assembly processes for the required components. In addition, the steps for assembly, handling and production in e‑car manufacturing are not yet as standardized as for internal combustion vehicles. This means that engineers and production managers have to rethink a number of aspects.

High degree of automation

E‑mobility requires highly flexible, customizable and versatile production processes. The upcoming conversion of e‑mobility to mass production while at the same time taking individual customer requirements into account cannot be achieved without incorporating automation in production.

During the conversion process, SCHUNK stays at your side as a competent partner, supplying everything– from the axis system to the robot accessories – from one source. This reduces the number of interfaces required and helps with the design and project planning.

Clever combinations

Even with our standard portfolio, there are plenty of individual processes that can be mapped out. On top of that, customers also benefit from the company’s many years of industrial experience and comprehensive engineering expertise. The well-known automotive manufacturers and their suppliers already enlist SCHUNK products, greatly accelerating their integration into new process chains.

Proven solutions can already be found on the market for the following three

component groups: the e‑drive, battery and fuel cell.

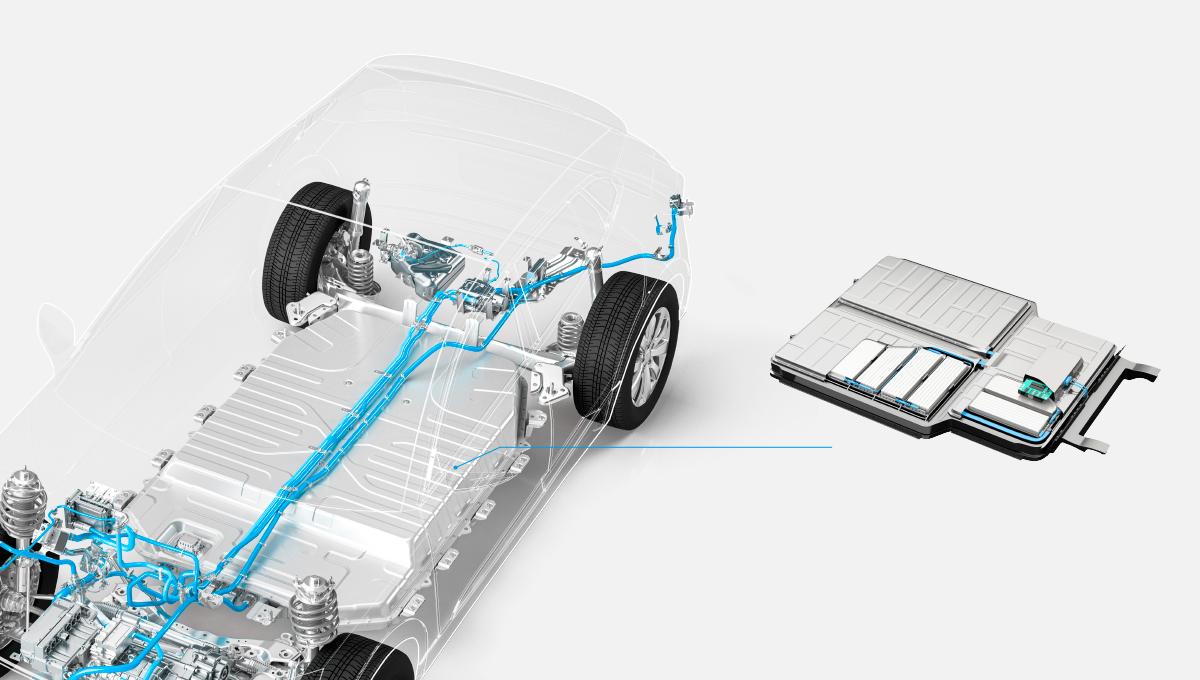

Battery systems

The entire automation spectrum is utilized in the manufacture of battery systems. This applies to high-speed handling of individual cells to handling the highest dimensions of battery modules and packs.

Round cell gripper

The magnetic gripper with pneumatic control is used for handling individual round cells. For use in production, it can be combined to form a multi-gripper.

Gripping module for battery packs

The gripping module is used when handling complete battery packs. Position deviations in the process can be compensated in conjunction with the heavy load compensation unit.

Gripping unit for prismatic cells

The long stroke of the gripper allows handling of different cell formats. The finger geometry allows multiple prismatic cells to be gripped and gathered simultaneously.

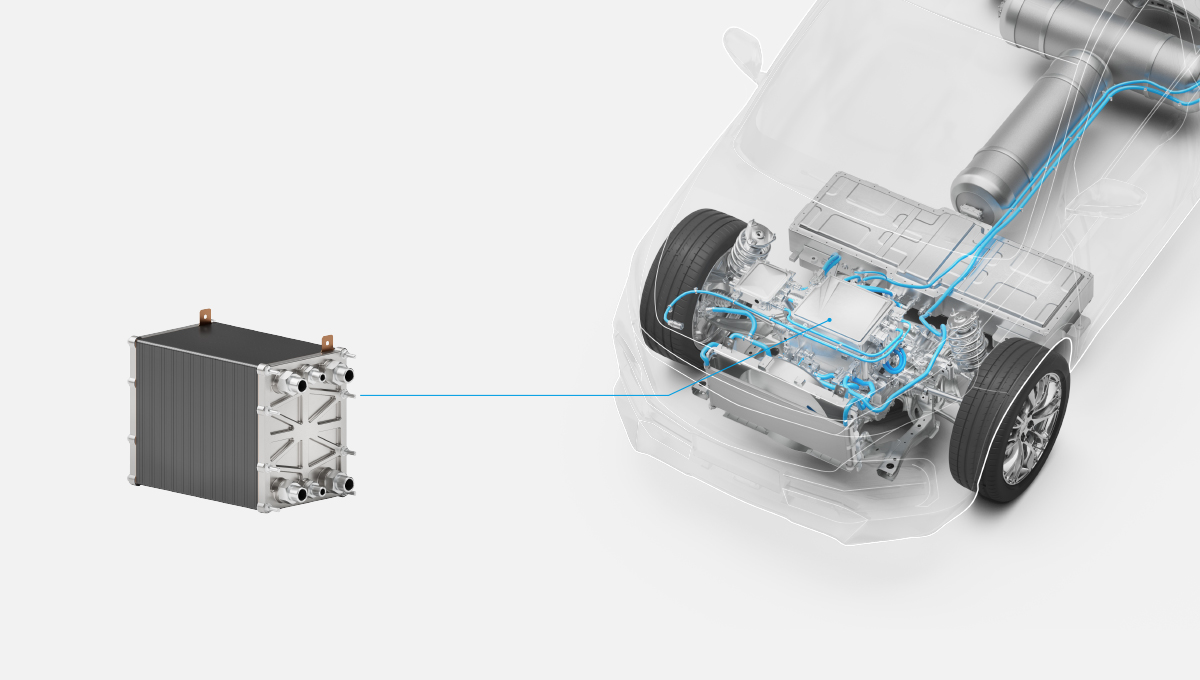

Fuel cell

Fuel cells have a high energy density and a short refueling time. That is why they are increasingly being used in mobile and stationary applications. SCHUNK offers extensive solutions for handling fuel cells and their components.

Stacking unit

Linear direct handling and large-area grippers can be used to assemble bipolar plates and membranes into fuel cell stacks.

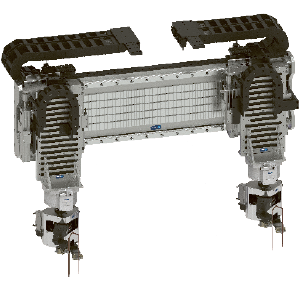

Linear handling gantry for fuel cell stacks

The axis gantry with gripping unit is used for handling of finished stacks. The long, freely programmable stroke of the gripper enables handling of different module sizes.

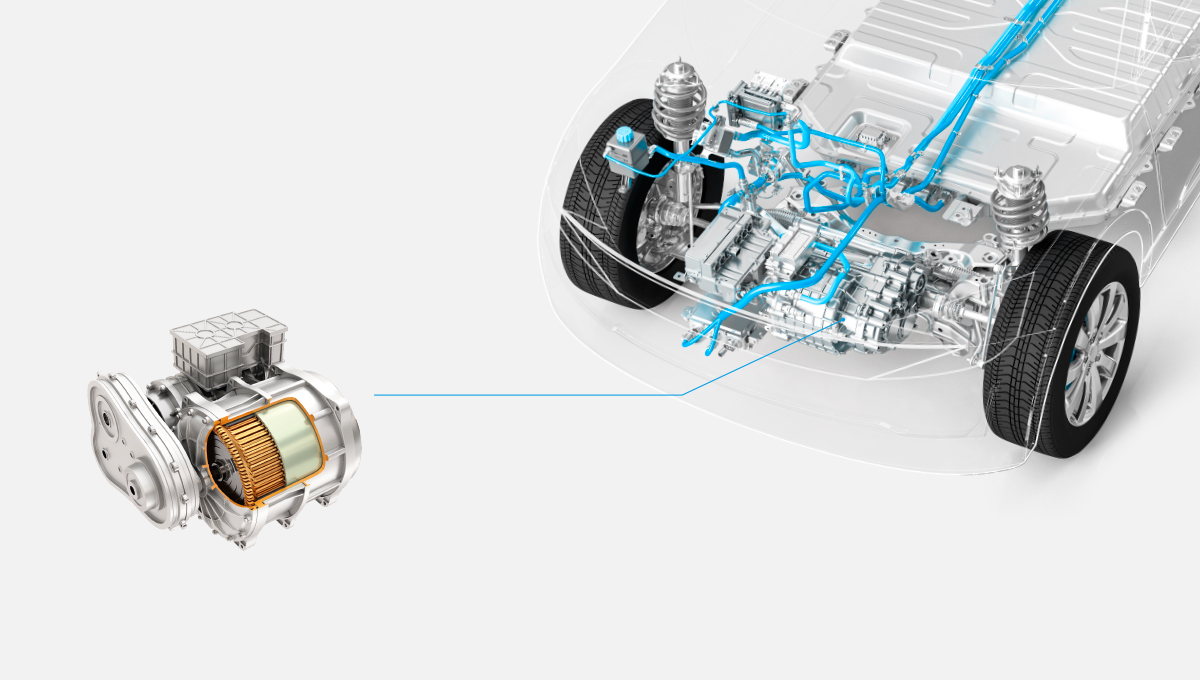

E‑drive

Electric motors place the highest demands on automation. Whether it concerns the specific setting of the hairpins, the handling of the sheet packages or the assembly of the components to the finished e‑axis: SCHUNK supports you.

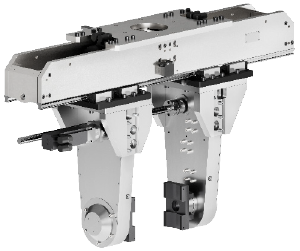

Handling unit with hairpin grippers

The handling and specific setting of hairpins requires high flexibility, dynamics and precision. The handling unit with two Z‑axes and two hairpin grippers allows hairpins to be placed in the stator in under one second.

Gripper unit for stator production

The long-stroke gripper is especially suitable for handling parts of different diameters. Stator housings, rotors, and electrical sheets can be flexibly gripped and turned using swivel fingers.

SCHUNK offers these added values

Concepts & validations of

- Gripper applications

- Handling tasks

- Clamping tasks

Everything from a single source

- Reduction of interfaces

- Design & project planning (mechanical, pneumatic & electrical, thermal)

In-house manufacturing

- High vertical range of manufacture

- Assembly according to specifications

- Documentation

Interested?

Tell us more about the application you want to automate. Our application experts will find the right solution together with you.

e‑mobility@de.schunk.com

Learn more:

schunk.com/e‑mobility