Unique rims, extremely fast and individual: That is the core promise of ROC Fertigung24. To deliver on this promise, the impressive toolholder portfolio from SCHUNK has also taken its place on the starting grid.

For a long time now, rims have been much more than just wheels, choosing the right rims is paramount for many car enthusiasts. The personality of modern car owners is not only reflected in the choice of model, but also in the individual design of the wheels. Whether pink or gold, small or large, simple or eye-catching – there are no limits to your imagination.

ROC Fertigung24 in Freudenstadt has been turning the dreams of wheel enthusiasts into reality since 2017. The material used is mainly aluminum, at the industrial estate on the B294 around 30 tons are sold per month. This results in forged wheels of up to 25 inches in diameter. All this variety would not be possible without the extensive range of toolholders from SCHUNK.

Flawless rims due to sturdy tools

“Our parts are first turned and then milled,” explains Managing Director Lukas Betz. The basic shape is first turned from a blank on a horizontal CNC lathe. This is then machined on 5‑axis milling machines from DMG. In doing so, ROC Fertigung24 relies on a considerable range of milling cutters in a wide variety of sizes. By the end, the finished rims include some highly delicate details, all of which also have to have a flawless surface finish because the rims are painted.

This means that nothing can go wrong during milling. The requirements for tool holders and tools are high. “The tool has to be stable for us and have a certain unclamping length. However, long cantilevers are sensitive to vibrations,” explains Betz. “That’s why you need absorbent holding systems. This is where SCHUNK’s hydraulic expansion toolholders are the right choice because they dampen the vibrations.”

ROC Fertigung24 shareholder Tobias Haug concurs: “There is nothing better for us.” With SCHUNK, we have found a partner at an equal level, which is also available for consulting. At the beginning of the collaboration, for example, it was not clear whether heat shrinking technology might be the better choice for toolholders instead of hydraulic expansion technology. We conducted experiments together.

It quickly became clear that, compared to heat shrinking, use of hydro-expansion and polygon clamping technology offered a better energy balance on the one hand, and better processing results on the other. An additional positive effect was that the tension could be applied more quickly by means of mechanical action. Thus, the numerous tool changes were not only more sustainable, but also more efficient.

Production in just three days

Because speed is one of the core topics at ROC Fertigung24: “Many of our customers assemble their rims individually via our online configurator using their CAD data,” says Mr Betz. “Then, when an order comes in, we get it ready within three days.” This speed is also expected from SCHUNK when something doesn’t fit. “We can count on fast service there,” Betz said.

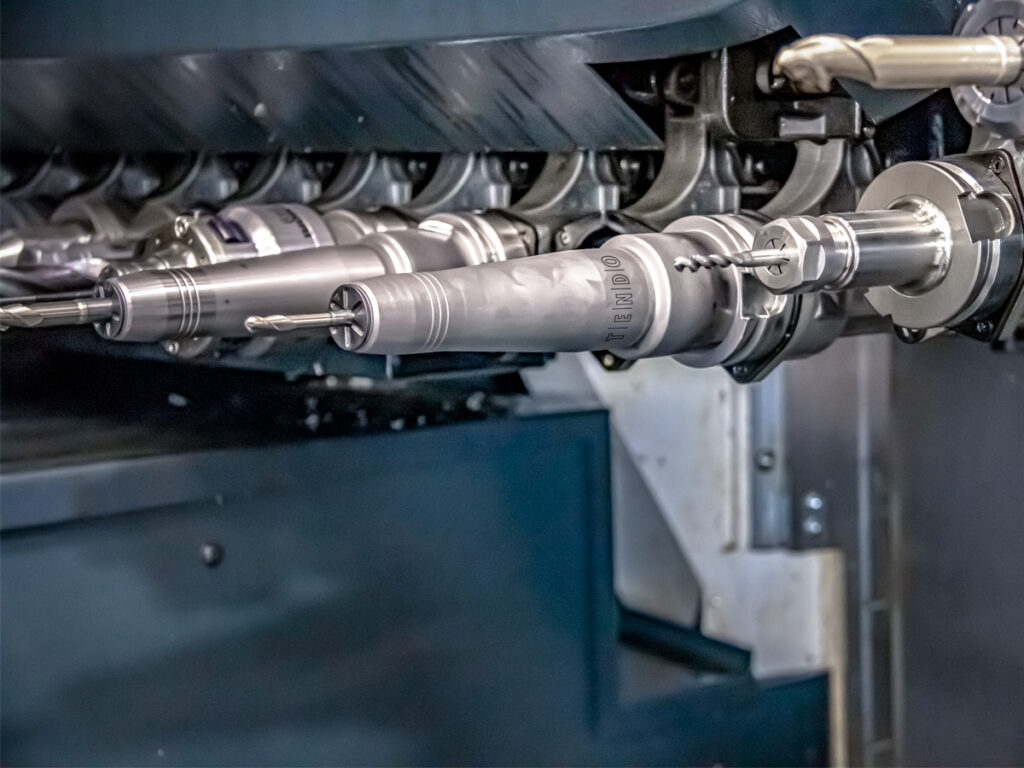

“Our total tooling concept comes into its own here,” stresses Hermann Winterer, the SCHUNK technical consultant in charge, glancing around the machine shop of the rim manufacturer. Betz explains, “We have everything here from 700 size jaw chucks to all tool holders, TENDO E compact, TENDO P, TENDO LSS, and a wide variety of intermediate bushings increasing flexibility.” The clamping technology components are used in six DMG Mori DMU75 monoblock 5‑axis milling machines, among others.

Depending on how much or little removal is required, ROC Fertigung24 moves at both ends of the spectrum when it comes to toolholders, for example with the small TRIBOS Mini polygon toolholder for ultra-fine machining or the slim TENDO Slim 4ax for machining close to interference contours. Other SCHUNK clamping technologies are also used at ROC, such as the SINO‑R expansion toolholder and the extremely slim TRIBOS‑S polygonal toolholder. Mechanical toolholders such as ER collet chucks and WELDON arbors complete the manufacturing requirements.

The right tools for the job

In the case of the TRIBOS Mini, the outstanding dynamic runout of < 0.003 mm is particularly important for ROC Fertigung24 — after all, the noble rims demand the maximum surface quality. Micro-blowouts on the tool cutting edge is avoided by the excellent vibration damping of the TRIBOS polygonal clamping system.

„With SCHUNK we can rely on quick service.“

Lukas Betz, ROC

With the TENDO Slim 4ax, ROC Fertigung24 sometimes machines very deep in the Z axis. Rim experts benefit from the fact that it is the only toolholder in its class with a heat-shrinking contour according to DIN 69882–8. Its robust base body prevents lateral deflection during the cutting process. The enormous clamping pressure inherent in all SCHUNK TENDO hydraulic expansion toolholders also enables ROC to machine job after job without compromising reliable torque transmission. The enormous clamping pressure creates a displacement of oil, grease or grease residue into the dirt groove and the clamping surface remains dry.

When it comes to clamping, the company still sees potential for joint development in the future. Due to the large overhang of the tool and the depth of the rims to be machined, the clamping table has to be very narrow. At the same time, however, it must also provide perfect support at high rotation and centrifugal forces. “Unfortunately, physics restricts us here,” says Mr Winterer. So far ROC Fertigung24 has relied on a home-grown solution, but is looking to close cooperation with SCHUNK. “Of course, it would be better if there was something from SCHUNK,” says Managing Director Haug. “We’re on it,” assures Mr Winterer.

Find the right toolholder with just a few clicks

The toolholder quickfinder from SCHUNK makes finding the appropriate tool mounting quickly and convenient. Just enter a few details about the interface, clamping diameter, projecting length and clamping technology and the tool will provide a clearly structured list of all relevant toolholders from the most comprehensive range of toolholder technology made in Germany. The underlying catalog program includes mechanical toolholders from the SCHUNK basic segment as well as cost-efficient hydraulic expansion toolholders from the economy class up to numerous hydraulic expansion, polygonal and expansion toolholders from the premium and tech classes.