Rädlinger Maschinenbau has gained significantly more safety, ergonomics, and efficiency in sheet metal handling with the TRETEL electropermanent magnetic module cross beam from SCHUNK. The heavy-duty cross beam optimizes the material flow and raises productivity to a new level.

A lot is going on at Rädlinger Maschinenbau in Cham, for example, excavator buckets and wheel loader buckets requiring handling are moved along the production line. There is also a lot happening in terms of production logistics and process optimization. “We are gearing up for the future,” explains Simon Fischer, Cham Plant Manager at Rädlinger Maschinenbau. “With a high level of investment, we are getting our production ready for the year 2033. Our goals are clear: greater efficiency, greater safety, and even more flexibility. We are investing a lot of money in this, and turning things upside down.”

The family-owned company has grown organically over time. “At some point, it became clear that we needed new structures here at the Cham site, and that we had to rethink our processes.” Fischer and his team took a year to reorganize the material flow.

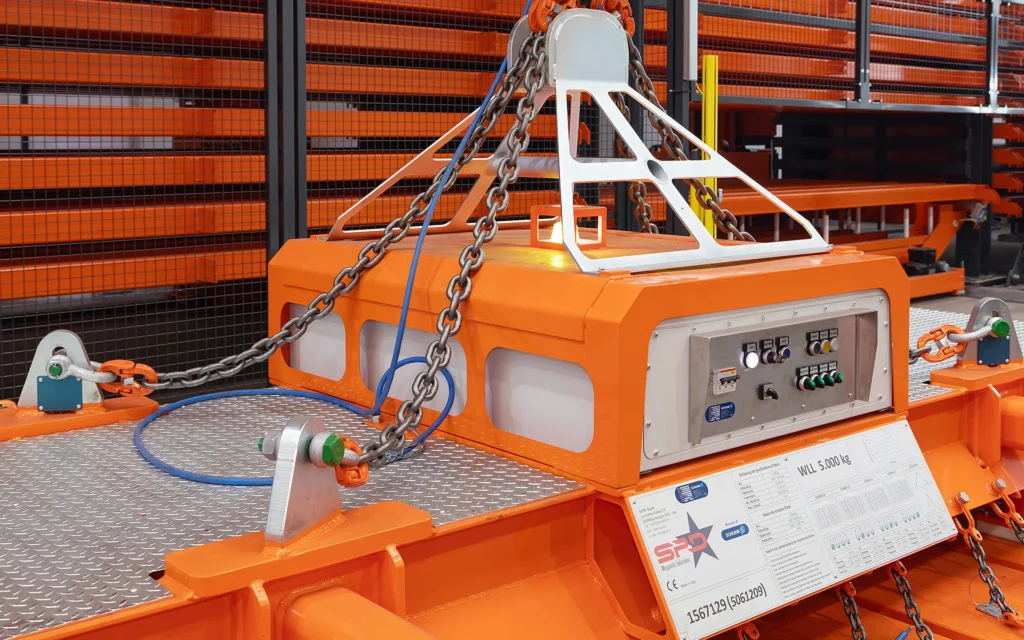

This included setting up a new hall with a new flame-cutting system and the new Stopa Compact storage center. A key question was how these two process stations could best be linked. “We were looking for a link for sheet metal handling between the cutting machine and the warehouse,” reports Fischer. Full automation was out of the question due to the sheet thicknesses, dimensions, and weights. This is how the electropermanent magnetic cross beam from SCHUNK came into play.

“High quality, always quick help, and absolute reliability – that’s how we see SCHUNK.”

Martin Grassl, Project Manager at Rädlinger Maschinenbau

Growth requires an adapted material flow

The specialist for clamping technology, gripping technology, and automation technology has been a cooperation partner of Rädlinger for years, because clamping devices from SCHUNK are naturally part of the operating equipment on the lathes in Cham. “We have been working with SCHUNK for many years,” says Martin Grassl, Project Manager at Rädlinger Maschinenbau.

“With SCHUNK, we have a partner-like adviser at our side, especially when it comes to the magnetic clamping technology on our milling machine. High quality, always quick help, and absolute reliability – that’s how we see SCHUNK.” Based on this positive experience, the Rädlinger team involved SCHUNK in the new lifting technology project. “Because SCHUNK stands out due to its magnetic clamping technology,” emphasizes Grassl. This led to the decision in favor of the TRETEL electropermanent magnetic module cross beam for handling metal sheets between the flame-cutting machine and the sheet storage system. Commissioning took place at the beginning of January 2025. “After a week of familiarization, it was clear that we had done the right thing,” says the project manager. “We have made significant gains in terms of safety, ergonomics, and process efficiency thanks to the surface magnet, while at the same time the process paths, set-up times, and space requirements have been noticeably reduced.”

Optimal machine utilization and process acceleration

Before the reorganization, Rädlinger used a forklift to remove the sheets from the blank warehouse, placed them on the cutting table by crane, and transported the components away again by forklift after the cutting process. “This conventional method of handling was laborious and not without danger,” says Martin Grassl.

“The surface magnet gives us the advantage that we can unstack the sheet from the blank store and place it on the cutting table all in one movement, and then completely lift off the workpieces together with the scrap skeleton after the cutting process with a single stroke. This significantly accelerates the process, because the cutting system with its high hourly throughput rate no longer stands still.” Without the surface magnet, productivity would be slowed down by around 50 percent, but now Rädlinger can utilize the full performance of the Microstep MG. While the machine continues its work, the cut parts are separated, and the scrap skeleton is deposited separately. Thanks to the magnetic cross beam, workpieces are handled outside the cutting system in parallel while machining continues. “This boosts our productivity,” says Simon Fischer, “and will pay off quickly.”

Employee protection and significant ergonomic gains

The new lifting technology has been well received: “Acceptance among employees is very high and they are enthusiastic about the benefits of the new processes,” says Grassl. One worker operates the magnetic cross beam, while a second helps to separate the cut components, which no longer have to be picked up from the table with a magnet. “The convincing arguments in favor of the magnetic cross beam were not only the faster machine loading and unloading, but also an improvement in the areas of occupational safety and ergonomics,” explains Martin. “In view of the shortage of skilled workers, we want to protect our employees as effectively as possible while offering them a pleasant workplace.” In this way, the new solution contributes to an ergonomic working environment. The control system also benefits the operator in terms of safety and ease of operation; it is controlled by two-hand operation on the control panel of the cross beam when not in use, and by radio remote control during the lifting and transport phase. SCHUNK has designed all the operating elements to be of high quality, clearly arranged, and labeled, which the user greatly appreciates.

Electropermanent lifting technology for complete safety

The electropermanent magnetic chucks only require a short current pulse for magnetization or demagnetization – no continuous current is necessary. In pick-up mode, the operator lifts the sheet a few centimeters at 75 percent power and checks that the load is centered and the air gap behaves acceptably. With this partial load function, safety is guaranteed at all times and in all conditions. This is followed by full magnetization at 100% power for the lifting and transport process. A central safety lamp on the cross beam indicates the switching states. Even if shear forces act in transport mode, shearing of the load is ruled out; triple safety is naturally provided in the design, taking into account operational conditions such as material, surface quality, and roughness.

Controlling the load lifter by radio remote control ensures a safe distance from the operator and helps to prevent accidents. Demagnetization is only possible when the load has been removed and the chain sling has been relieved. This is monitored by two redundant safety lifting eye switches arranged diagonally at the chain sling attachment points; they prevent the load from falling during the lifting phase due to unintentional actuation or incorrect operation. This ensures comprehensive safety in the event of a power failure or overvoltage. Any incorrect operation on the cross beam or via radio remote control is also ruled out.

Maximum flexibility in the sheet metal handling process

At Rädlinger, the surface magnet handles all sheet metal panels in all grades, sizes, and thicknesses up to five metric tons in weight. High-alloy steels such as HARDOX are often used; the requirement here is for the sheets to be completely demagnetized again, so they can be used in subsequent processes without any problems. Quality losses due to any residual magnetization on the material are ruled out. “We can adjust the holding force in four stages and lift individual sheets with a thickness starting from five millimeters in a defined manner. This gives us unparalleled flexibility in sheet metal handling,” explains Martin Grassl.

The magnetic lifter can be used to feed the metal sheets individually into the flame-cutting system and lift them off after cutting in a single operation, together with the workpieces, scrap skeleton, and cutting waste. The sheets can be fed to the Stopa sheet storage system individually or in sheet packs – SCHUNK has integrated transport hooks and chains as special equipment for this purpose.

The production of construction machinery equipment at Rädlinger also benefits from the future viability of the system, as the load lifter can be expanded with additional magnet modules if required. “We found a great solution together,” says Project Manager Martin Grassl. SCHUNK had clearly worked out the advantages and special features, which was an important aspect in the decision for the TRETEL cross beam. “Added to this is the implementation of our individual wishes and requirements – for example, the entire system in the color of our choice – as well as smooth commissioning,” adds Grassl. “SCHUNK spent a lot of time on us and worked hard to ensure that we got the best result.”

Electropermanent magnetic cross beam closes the loop

represents a quantum leap for us,” summarizes Simon Fischer. The plant manager sums up the advantages: “Less space required, optimum machine utilization, forklift-free operation, improved worker protection and ergonomics as well as a massive reduction in handling times, setup effort, and path lengths per product,” says Fischer, working his way down the list.

“The lifting technology adapts flexibly, we have gained transparency and traceability, and we can largely eliminate search times in make-to-order production. What’s more, the electropermanent system is environmentally friendly because we use less energy. This means we are well equipped for the future.”