MAG LaserTec uses “Laser Metal Deposition” to apply a coating to brake disks, thereby reducing the release of fine dust. For shorter setup times and higher process reliability, EMAG chose the pneumatic PLG long-stroke gripper and the GFS swivel fingers from SCHUNK. SCHUNK Engineering achieved this efficiently and precisely.

Clever solutions are sometimes needed very quickly. Solutions like the new system from EMAG LaserTec. It applies a hard metal coating to brake disks using laser deposition welding. The technology is urgently needed because it prevents abrasion and thus particulate matter from being produced during the braking process. The particles are hazardous to health. This is why the new Euro 7 emissions standard will regulate all vehicle emissions from newly registered cars from 2027 – including wear and tear from brakes and tires. So, speed is of the essence. When selecting the components, the EMAG development team therefore relied on SCHUNK Engineering. Thanks to this efficient process, EMAG was able to obtain precisely tailored components for its specific requirements in the shortest possible time.

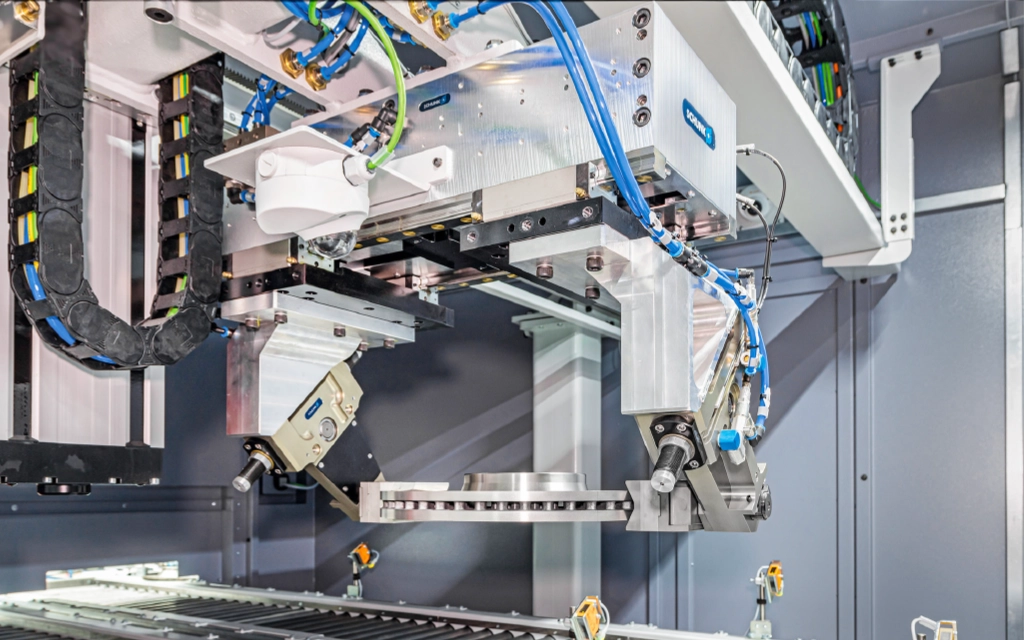

PLG long-stroke gripper on an integrated handling system

“We launched the ELC 450 LMD so that our customers can meet the requirements for the brake disk of the future. It uses ‘Laser Metal Deposition’ (LMD) to apply a two-layer coating to the brake disk, which makes it practically impervious to wear and corrosion, while significantly reducing fine dust emissions,” confirms Martin Fritz, Development Team Leader at EMAG LaserTec in Heubach. “SCHUNK provided us with significant support in realizing the automated component feed to the laser cell in a compact and reliable process, and with a specified cycle rate. The pneumatic long-stroke gripper PLG is used in conjunction with GFS universal swivel fingers – this is a convincing handling solution for us in the new machine.” The EMAG design engineers installed the long-stroke gripper on a line gantry in the ELC. “We were able to dispense with a classic robot for component feeding, because there is no room for it in this cramped workspace,” says Martin Fritz, explaining the ELC environment. “The existing linear handling from EMAG and the SCHUNK PLG gripper together with GFS swivel fingers result in ideal kinematics for the brake disk infeed and outfeed.”

“SCHUNK helped us to implement the automated component feed in a reliable, compact, and fast way.”

Martin Fritz, Development Team Leader at EMAG LaserTec

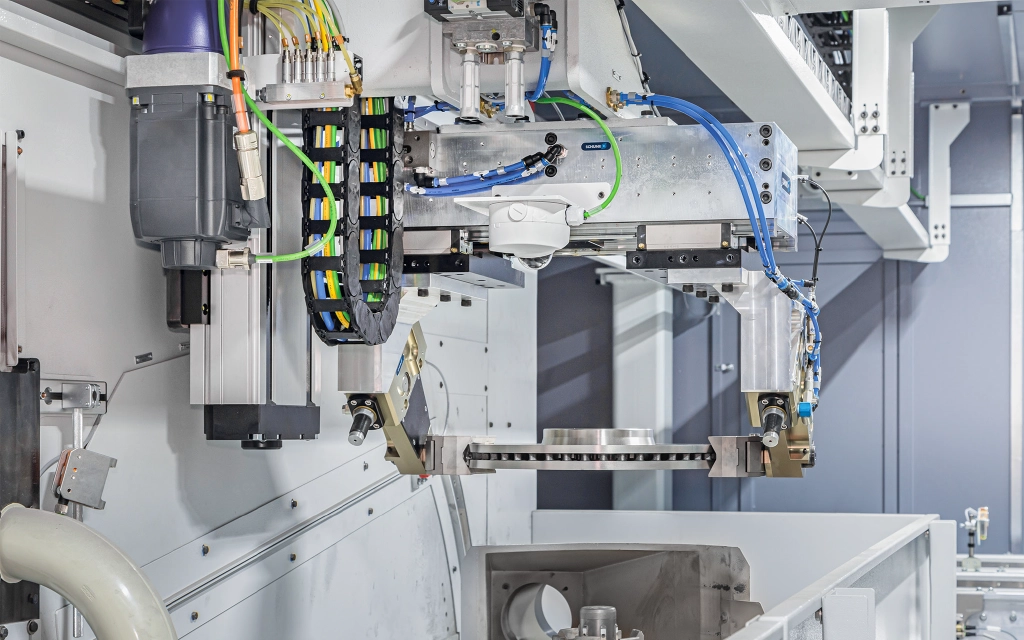

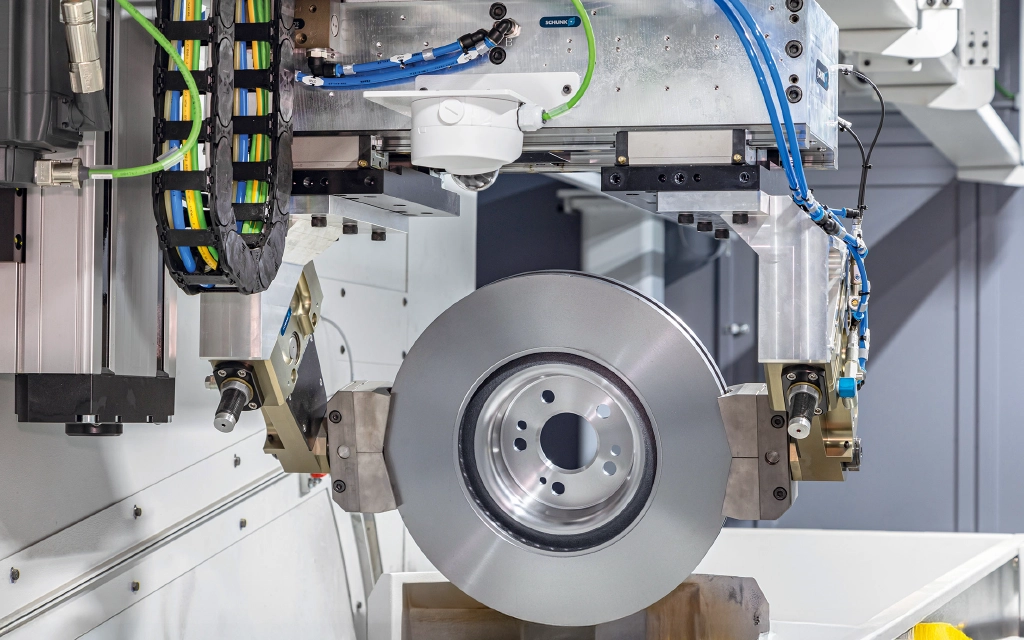

PLG with GFS feeds the brake disks into the coating cell

The compact loading and unloading solution in the workspace of the ELC 450 LMD DUO proves to be robust in the operation of two laser cells. The PLG starts its work at the roller conveyor by picking up the pre-centered gray cast-iron brake disk, which weighs around 30 kilograms. It will have been cleaned, weighed, and preheated to about 300 degrees Celsius in upstream processes, and can be fed to the roller conveyor in manual, semi-automated, or fully automated mode. The PLG now guides the horizontal disk to the mounting spindle of the first laser cell. This is where a stainless-steel corrosion protection layer is applied. After the hermetically sealed laser unit has released the disk, the PLG lifts it off the spindle and turns it using GFS swivel fingers before placing it back on the arbor. The second side of the disk receives its corrosion protection layer next. When the first laser station has finally released the disk, the handling system moves to the next station above the suction funnel. The disk is also turned over above the funnel, in order to vacuum it on both sides. Finally, the PLG feeds the disk horizontally to the second laser station, where the hard carbide layer is welded in on both sides.

In the two cells of the ELC 450 LMD DUO, the coating material is fed in as a powder and fused onto the component surface by laser. After a total of four coating processes – two disk sides and two cells – the brake disk is ready to be unloaded. Inline quality assurance measures, such as a layer thickness sensor, ensure the separation of NOK parts integrated into the process. The PLG brings the finished coated brake disks to the exit point from the ELC workspace on the corresponding roller conveyors for parts removal; downstream processes then take place.

Defined specifications are quickly fulfilled thanks to online configuration

“Our specifications for the gripper in this new machine concept were very clearly defined,” summarizes Martin Fritz: a long stroke for a disk-shaped component with a diameter of 250 to 500 millimeters, force for a workpiece weighing around 30 to 50 kilograms, a gripping height of around 10 to 45 millimeters, and sufficiently robust for an environment with residual metal dust. “The ELC’s tight workspace set further constraints,” says the Development Team Leader. “The solution has got to be compact. We want the component to be fed and discharged in a horizontal position, and the open gripper stroke always to move in the process direction. Freedom of setup across a defined range of workpieces is also a requirement, because we want to be able to grip all disk sizes with just one set of jaws. We also need safety: analog monitoring of the jaw stroke provides us with a way of knowing immediately whether the correct workpiece is being gripped. Last but not least, swiveling should be quick.”

The benchmark is scope for future development

A sophisticated machine concept for the brake disk production of the future requires equally sophisticated components. It quickly became clear that the newly introduced long-stroke gripper from SCHUNK was the right solution. “Configuring the gripper together with Jürgen Kolbus here at the desk made the work much easier, and saved a lot of time,” confirms Martin Fritz. “It took only a few minutes, and we had our CAD. After less than an hour, we were able to see directly in the Design department whether everything fitted.” Special solutions in industrial manufacturing are often associated with high costs and long delivery times. SCHUNK’s quickly configurable product ranges are the answer to this problem: customers receive an individual, affordable solution quickly, even for small batch sizes and high demands. The GFS swivel fingers with a swiveling time of only 0.8 seconds were the deciding factor for EMAG in choosing this solution: “The GFS fingers from SCHUNK were the best solution for the specific process,” emphasizes Martin Fritz. EMAG installed the PLG with size 50 in the ELC 450 LMD DUO, and met all the specifications with it.

A complete, fully automated process in the coating system takes just under four minutes. Reduced setup and idle times, 24/7 automation, fast cycle rates – for EMAG, the new laser application system must meet the high quantity requirements resulting from the entry into force of the Euro 7 standard. The PLG in combination with the GFS swivel fingers significantly supports this objective – in terms of quality, safety, and speed of the process.

1.

Gripping the brake disk

The PLG’s work on the integrated handling system starts with picking up the gray cast-iron brake disk, which weighs around 30 kilograms.

2.

Feeding to the laser station

The line gantry with the PLG feeds the brake disk to the spindle of the first laser machine tool.

3.

Turning the brake disk

The GFS with prism jaws handle and flip over the brake disk.

4.

Removing the brake disk

The now fully coated brake disk is lifted out at the second laser machine tool.

What is SCHUNK Engineering?

SCHUNK Engineering means that the experts on the customer side and from SCHUNK work together to develop new, innovative, and economical solutions – worldwide. SCHUNK accompanies the customer’s processes right from the start in order to understand them and optimize them through customized product developments. The basis for this is the extensive component portfolio along with the industry and application expertise that has grown over decades. As a reliable partner, SCHUNK is at the customer’s side from the initial inquiry, through development and simulation, to production and after-sales service. The spectrum ranges from the customized development of a single product in large quantities to a comprehensive, tailor-made solution as part of a system.

More about this topic:

A forward-thinking solution!

Learn more:

Gripper configuration PLG